Armico Blog

Properties and Applications of Basalt Fiber and Its Composites

Basalt fiber is a green, healthy and environmentally friendly high-tech fiber product without environmental pollution. It is widely used in military and civilian fields. It is not only of great theoretical significance but also of great strategic significance to strengthen the analysis and study of the properties of basalt fiber and its composite materials. The results show that: compared with glass fiber, carbon fiber and aramid fiber, basalt fiber has good mechanical properties, acid-alkali resistance, excellent electrical properties, high wave permeability, non-conductive, and excellent sound insulation and insulation performance. Based on the above advantages, the combination of basalt fiber and substrate can enhance the material properties. Based on the above features, the basalt fiber and its composites can be made into high temperature and low temperature protective clothing and sound insulation materials used in sound absorption and heat insulation industry. Its production can also be widely used in the fields of brake, electric, electromagnetic and so on for its unique features.

1. Introduction

High-tech fiber is of great importance to national construction and a key foundation for supporting the development of high and new technology industry[1]. In recent years, the market demand of high-tech fiber composite material products in China is growing faster and faster, with an average annual growth of 30%. According to the current situation of China, it is necessary to develop and utilize a kind of high technology fiber with low price, excellent performance and independent intellectual property right to meet the high-speed developing society. The basalt fiber is a new material which is widely applied in military and civilian area, such as aerospace, architecture, chemical industry, medicine, electronics, agriculture. It is known as the new material of the twenty-first Century[2,3].

The price and the quality of the fiber are difficult to control. Japan has an absolute monopoly on carbon fiber and the research on carbon fiber, aramid fiber and ultra-high molecular weight fiber in the United States is also in front of China. Basalt fiber is the only green and healthy glass fiber product without environmental pollution. With the continuous development of social economy, people’s understanding and application of basalt fiber is deepening, and the market demand for basalt fiber and demand of its products is increasing fast.

Researches of basalt fiber are still in the primary stage, the study of the performance of basalt fiber and its composite materials in China is not only of great theoretical significance, but also of great strategic significance.

2. Basalt fiber and its manufacturing process

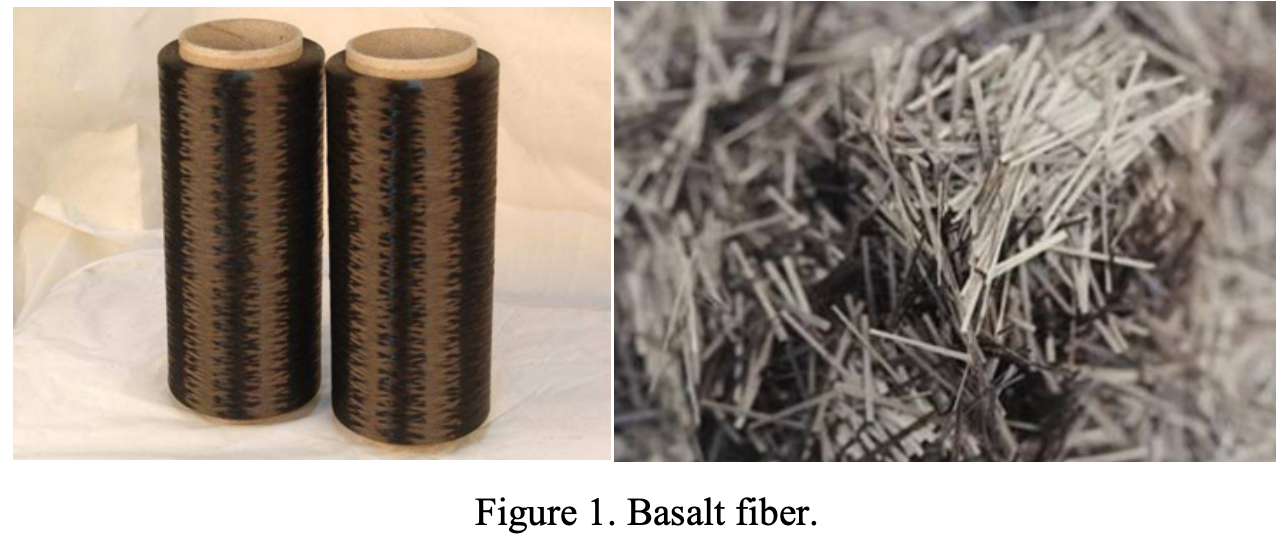

2.1. Basalt fiber

Basalt fiber is a continuous fiber made of melting basalt stone at 1450 to 1500 degrees through Platinum rhodium alloy bushing. It is a new environmental protection fiber which is known as the twenty-first Century ‘volcano rock silk’, it is also called golden fiber because its color is golden brown.

2.2. Equipment and technology

The raw materials and energy are basalt, gas, electricity, and impregnating compound.

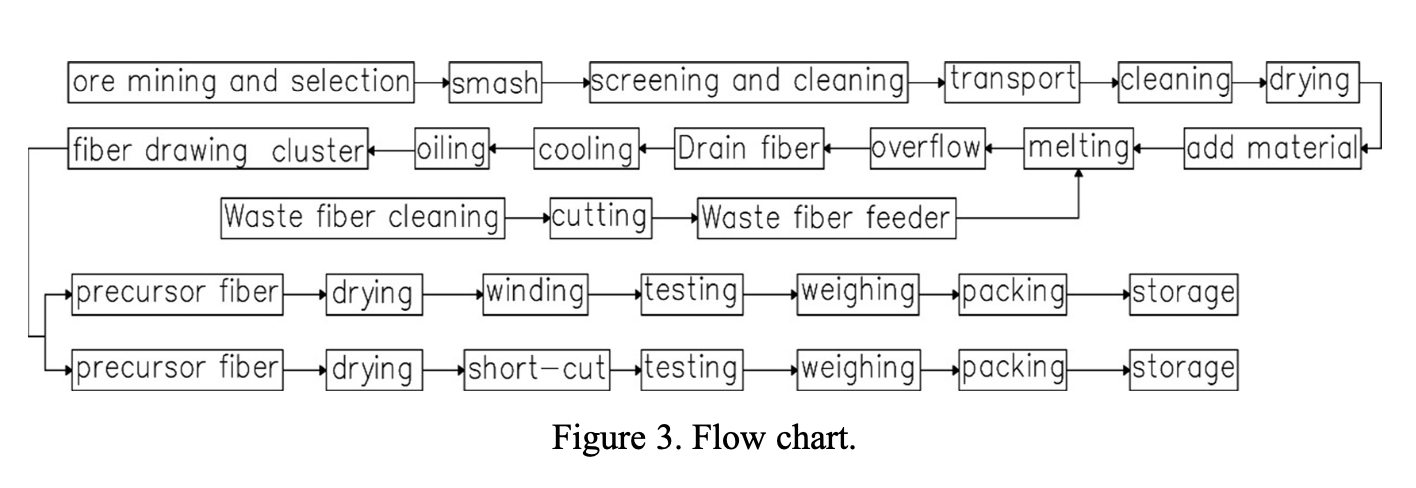

The equipment is gas or electricity wire drawing kiln, Platinum rhodium alloy bushing, crusher, applicator, impregnating compound configuration and conveying equipment, roving machine and loom. Figure 2 has shown the manufacturing process and figure 3 has shown the flow chart.

1-Bin, 2-Feeder, 3- Lift conveyor, 4- Quantitative feeder, 5- Primary melting zone of raw materials, 6- Natural gas nozzle, 7- second stage melting zone (front furnace), 8- Platinum rhodium alloy bushing, 9- impregnating compound configuration equipment, 10- buncher, 11- Fiber tensioner, 12- Automatic fiber winding machine.

Figure 2. Manufacturing process of Basalt fiber.

3. Basalt fiber production

Compared with other types of fiber materials, basalt continuous fiber have stronger affinity with other materials, such as various resins and inorganic materials[4]. This means that the composite has better performance. Continuous basalt fiber can be made into many composite materials with special enhancement characteristics.

Both for non-surface treated fibers or by silicone treated fibers, the bonding strength of basalt fiber and epoxy resin is higher than that of E glass fiber, which is also better than carbon fiber and high silicon oxygen fiber[5-6].

3.1. Principle and productions

(1) Composite with matrix to enhance the properties of the material[7]

Continuous basalt fiber has higher modulus of elasticity, better temperature resistance, impact

resistance and chemical stability than ordinary glass fiber, so the composite materials made up by various kinds of resins have ideal physical and chemical properties, and can be made into complex shapes for long-term use in high pressure, chemical and thermal stress environments. Basalt fiber reinforced composites can be comparable with S glass fiber or Aramid fiber reinforced composites in many occasions. Its cost is similar to or slightly lower than that of glass fiber. Its main performance indexes are much better than the traditional silicon aluminum glass fiber, even close to the expensive magnesium silicate fiber, and some properties are close to the carbon fiber.

1Basalt fiber reinforced composite bars

Basalt fiber reinforced bar is made of high strength basalt fiber and vinyl resin (epoxy resin) by spinning, winding, surface coating and compound molding. It is a new building material with the characteristics of high strength, excellent acid and alkali resistance and durability. Its hardness is 3 times of steel bar, and the density is only about 1/4 of steel bar. In some aspects of civil engineering, it can replace steel bar because it is a new, green, environmental, economical and high performance material. It can be used for layout of reinforcement net in Road (bridge) pavement, all kinds of anchors, and reinforcement for special occasions (earthquake monitoring station, etc.).

2Short cut basalt fiber.

Short cut basalt fiber Short cut basalt fiber is made from chopped continuous basalt fiber. This product can effectively enhance the impact resistance, wear-resistance, temperature shrinkage and freeze thaw resistance of concrete and mortar. It can be applied to cement concrete in roads, bridges, airport runways, dams and other projects.

(2)sound absorption and heat dissipation

Basalt fiber with suitable fineness and density can make basalt fiber have low thermal conductivity. This basalt fiber can be used as thermal insulation composite material[8-9]. At the same time, the basalt fiber can be used in high temperature and ultra-low temperature equipment, protective clothing of high temperature operation and low temperature thermal insulation because of its superior temperature range and thermal shock resistance.

Because of the porous structure and the irregular arrangement of the basalt fiber, the sound absorption capacity of the basalt fiber is good. The absorbability of basalt fiber is enhanced with the increase of the thickness of the fiber layer and the decrease of the density. The basalt fiber can be made into acoustic insulation composites for aviation, ship, mechanical manufacture and construction as a sound insulation material.

1Basalt fiber cloth

Basalt fiber cloth is made from basalt fiber with 7-13μm, such as woven roving, twill, satin cloth and plain cloth. These cloth has the advantages of non-flammability, flame retardancy, smoke-free, high temperature resistance, no toxic gas discharge, nice heat insulation, no melting or dropping, high strength, no heat shrinkage, etc. It can be applied to field welding, gas cutting protective equipment, fireproof cloth wall, textile, chemical, metallurgical, theaters, military workers and other ventilated fireproof and protective supplies, fire helmets and necked fabric.

2Basalt fiber high temperature filter bag

Basalt fiber high temperature filter bag with high tensile strength of basalt fiber, with high temperature resistance, acid alkali corrosion, oxidation resistance and stable size, can meet the harsh conditions of the dedusting operation, improve the efficiency of dust removal and prolong the life of the filter bag. It can be applied to dust collecting or collecting products in steel, chemical industry, cement, carbon black and food industry.

(3)Anti friction

At present, the most commonly used fiber resistant composite materials are steel fiber, glass fiber, aramid fiber, carbon fiber, asbestos fiber, but these fibers have their advantages and disadvantages. For example, steel fiber is high in strength and good in thermal stability, but it is high in density, easy to rust and easily damaged. Glass fiber is high in strength and low in price and easy to melt at high temperature, which will lead to the decrease of material properties and the instability of friction properties. Although the performance of aramid fiber and carbon fiber is excellent, but its price is very expensive; asbestos materials have excellent properties such as high strength, good surface activity, good friction and wear properties and dispersed and uniform mixture, but asbestos is a carcinogenic substance that endangers human health, and the pollution of asbestos dust is very serious. But the basalt fiber is not only with high strength, good thermal stability, not easy to damage duality, low wear and tear, the friction coefficient is stable, and the price is suitable, it will be the first choice material for non-asbestos fiber.

Basalt fiber friction composites are mainly used for automotive friction materials such as basalt fiber composite brake pad.

(4)Insulating materials and electromagnetic shielding materials

Compared with carbon fiber, basalt fiber has excellent non-conductive and electromagnetic properties, and can be widely used in power and radar and other military and civil engineering such as basalt fiber insulators, basalt fiber trolley wrists, basalt fiber Radome.

4. Comparison with common fibers

(1)Physical property

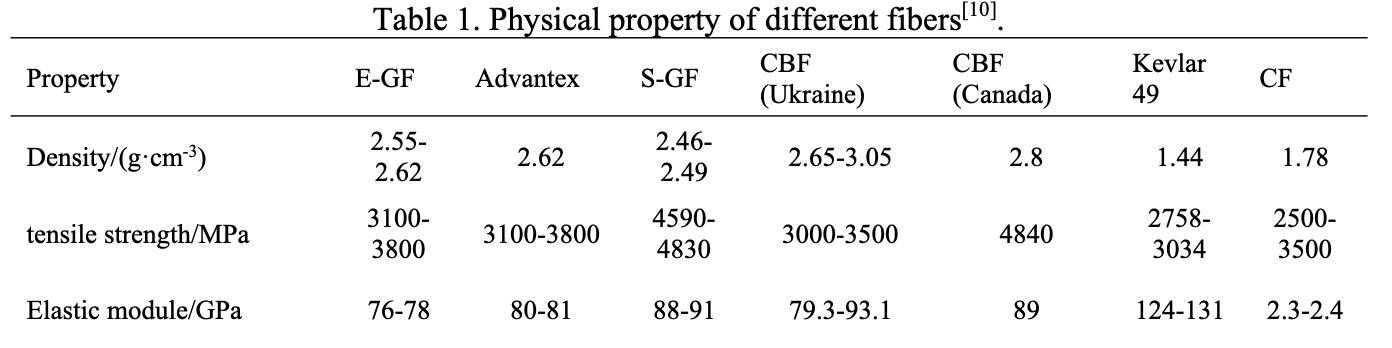

The continuous basalt fiber is not the strongest of all fibers from comparison of the performance,

but if we consider all the performance of fibers comprehensively, none of the fiber can reach the

continuous basalt fiber.

(2) Chemical properties

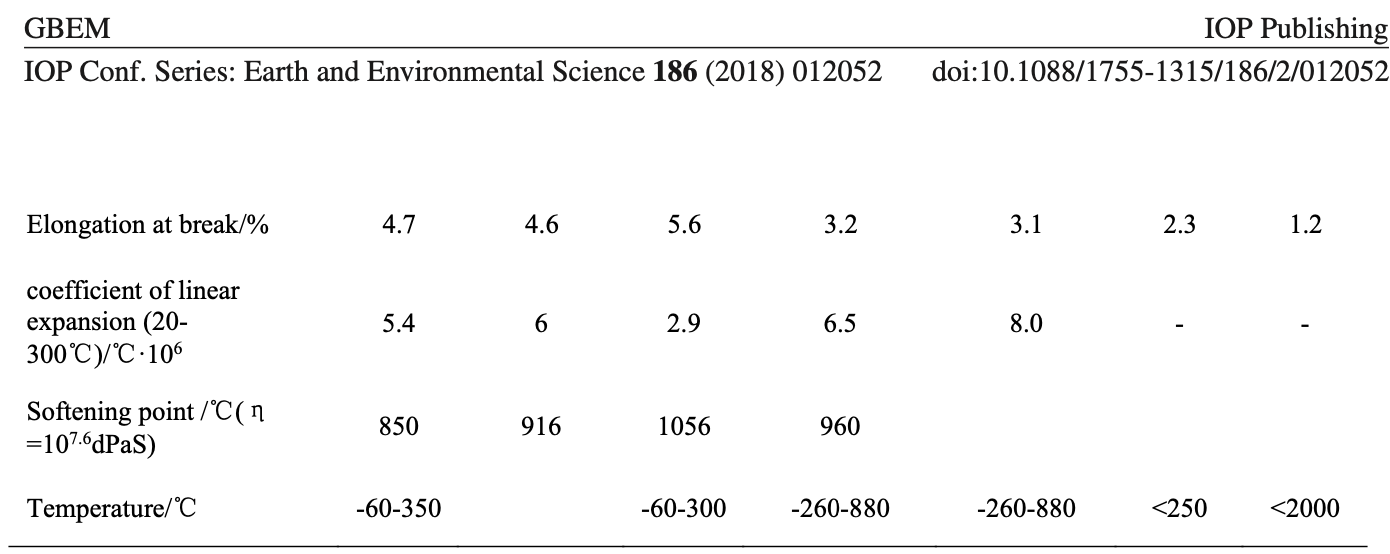

It is found that basalt fiber and glass fiber have good water resistance in table 2. After boiling for 3 hours in a strongly alkaline solution, the weight loss rate of basalt continuous fiber is 5.5%, while that of glass fiber reaches 45%. After boiling for three hours in acid solution, the weight loss rate of basalt continuous fiber is only 8.1%, far less than 25.3% of glass fiber.

Note: the above data is the weight loss of fiber after boiling 3 hours in different medium(%)

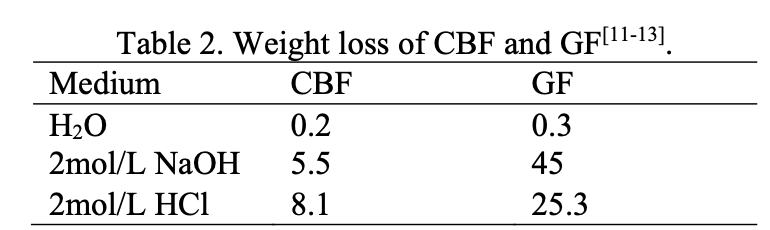

In acidic medium, it can be seen that after one hour of corrosion, the strength retention rate of basalt fiber can still stay above 50%. Because the acid resistance of glass fiber is relatively good, its strength retention rate is maintained above 80% after one hour of corrosion. However, under the alkaline condition, after one hour of corrosion, the strength retention of basalt fiber decreased to about 20%, and serious embrittlement occurred. The fiber has been highly fragmental and the strength retention rate has almost dropped to zero because of its volume integrity has been destroyed.

Note: the above data is the strength loss of fiber after boiling 1 hours in different medium(%)

From the perspective of weightlessness rate, basalt fiber has better alkali resistance than glass fiber. From the perspective of strength retention rate, basalt fiber has better alkali resistance than glass fiber. Combining two factors, we can see that basalt fiber has better alkali resistance.

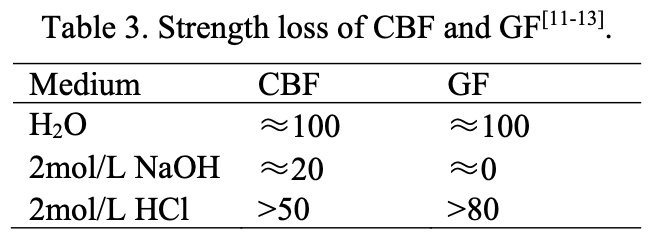

(3)Electrical properties

The dielectric constant of basalt fiber fluctuates near 2.61, and the dielectric loss fluctuates above 0.005, indicating that electromagnetic wave passes through basalt fiber. The loss is very small, that means the permeability of basalt fiber is better.

Compared with other types of fiber, the dielectric constant of basalt fiber is lower than that of other fibers. The dielectric loss of E-glass fiber, S-glass fiber and Kevlar fiber is in the same order of magnitude as those mentioned above.

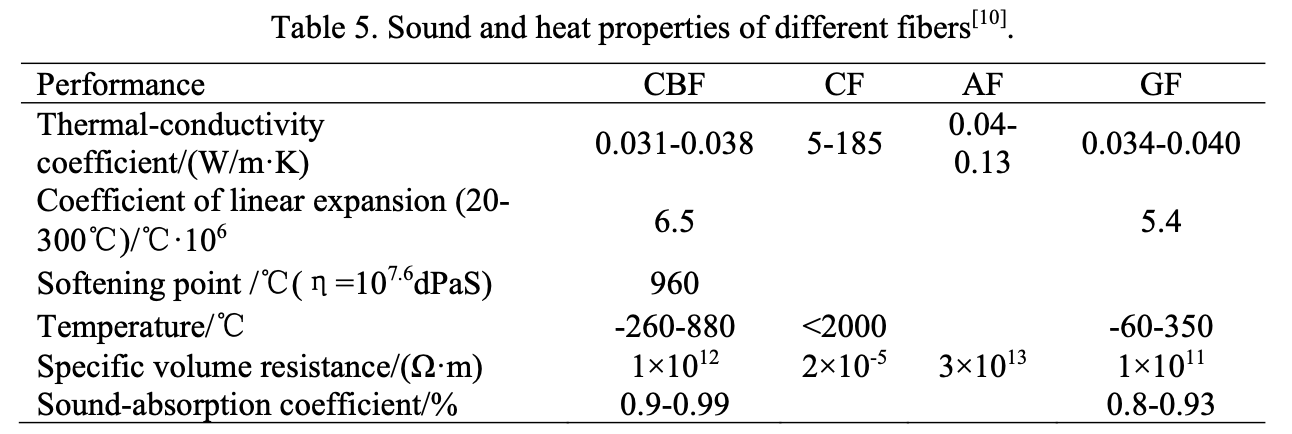

(4)Sound insulation and heat insulation

Basalt fiber can be used as an efficient thermal insulation material in low temperature technology. The thermal conductivity of the superfine basalt fiber with a unit diameter of 1-3μm (140Kg/m3) is 0.030W/(m·K) under the condition of -96°C, and the strength of the fiber is not reduced after soaking in the liquid nitrogen medium. Therefore, the Liquid Oxygen production department in metallurgical plant has used basalt fiber system for a long time. The heat insulation material made.

The sound absorption materials made of basalt fibers are widely used in the aviation industry, the shipbuilding industry and the machinery industry, and the fiber can be used to make structural materials combined with the insulation and sound absorption. This kind of material is absolutely non- combustible, and no harmful substance or gas is discharged under the condition of heating. The use temperature is up to 600-700 degrees centigrade. If combined with other materials, the temperature can reach 1000 degrees C, such as fireproof firewalls, safety fire doors, fire protection structures, cable hanger lines, and other industries. Some of the products of a high building in or in civilian use.

5- Summary

(1) Excellent mechanical properties: basalt fiber has excellent tensile strength and modulus of elasticity, and can be widely applied to reinforced composites.

(2) High corrosion resistance and chemical stability: basalt fibers have unique chemical stability in extreme conditions, it can be used in many concrete structures, such as bridges, tunnels, dams, floors, and other concrete structures, such as asphalt concrete pavement, aircraft landing runway, etc., which are often affected by high humidity, acid, alkali, and salt medium. The application in the structure has opened up a broad prospect.

(3) Basalt fiber has higher electrical insulation than glass fiber. It can be used as a heat-resistant insulating material in the field of printed circuit board manufacturing in the electronic industry. The permeability of the electromagnetic wave is excellent, if a basalt fiber cloth is added to the wall of the building, it can produce good shielding for all kinds of electromagnetic waves.

(4) High thermal stability and high acoustic and thermal insulation properties: basalt fiber is widely used in adiabatic insulation because of its low thermal conductivity, large working range and good seismic performance. In addition, basalt fiber has porous structure and irregular arrangement mode, and has good sound absorption property, so it can be used as acoustic insulation material for production equipment.

(6) Good compatibility with metal, plastic, carbon fiber and other materials: the composite of basalt continuous fiber and various kinds of resin has stronger bonding strength than glass fiber and carbon fiber. The composites made of continuous basalt fiber are equivalent to E-glass fiber in strength, but elastic modulus has obvious advantages in all kinds of fibers. If a certain amount of carbon fiber is added to the basalt fiber and interwoven with two different fibers, the modulus of elasticity, tensile strength and other properties of the composites will be greatly improved. Compared with the pure carbon fiber composites, the cost will be greatly reduced.

Acknowledgments

This paper is supported by the National Science Foundation of China. Grant No. 51178390

References

[1] Luo YF, Luo XM 2016 J. Great innovations of hi-tech fibers were coming. Hi-Tech Fiber&Application 41 1-13

[2] Lei J, Dang XA, Li JJ 2007 J. Characteristic, application and development of basalt fiber. New Chemical Materials 35 9-11

[3] Hu XQ, Sheng TN 2005 J. The Applications of the CBF in War Industry & Civil Fields. Hi-Tech Fiber&Application 30 7-13

[4] Sim Jongsung, Park Cheolwo, Moon Do Young 2005 J. Characteristics of basalt fiber as a strengthening material for concrete structures.Composites Part B Eng 36 504

[5] Schut JH 2004 J. Lava-based fibers reinforce composites. Plastics Technology

[6] K Zoltan, Sandor SJ, Tibor C 2004 J. Production and investigation of biologically degradable matrix polymer composites reinforced with basalt fiber. Muanyag Es Gumi/Plastics and

Rubber

[7] Hao YK, Xiao JY 2004 M. High performance composite materials. Chemical Industry Press

[8] Tatarintseva O S.Uglova T K,Igonin G S, et al 2004 J. Determination of operation times of basalt-

fiber thermal insulating materials.Stroitel’nye Materialy

[9] Takeuchi Kazuhiro, Osada Takeo 2004 P. Friction material. JPPat.2004331861

[10] Liu XH 2014 J. Comparison and characteristics of continuous basalt fiber, carbon fiber, aramid

fiber and glass fiber. Shanxi Science and Technology 29 87-90

[11] Huo WJ, Zhang ZG, Wang MC, et al 2007 J. Experimental study on acid and alkali resistance of

basalt fiber used for composites. Acta Materiae Compositae Sinica 24 77-82

[12] Shen QZ, Ji SH 2012 J. Effect of chemical corrosion on tensile properties of basalt fiber and

glass fiber[J]. Journal of China and Foreign Highway 32 239-243

[13] Yao Y, Xu P, Liu J, et al 2015 J. Comparative study on corrosion resistance of basalt fiber at

home and abroad[J]. China synthetic fiber industry 38 9-11

[14] Yao Y, He YC, Chen ZW 2016 J. Microwave dielectric properties of basalt fiber and Its

Composites[J]. Fiber Reinforced Plastics/Composites 5 65-67

Arab Mining company – Fujairah

Arab Mining Company – Fujairah was established in 2018 as a limited liability company with main focus toward the mining activities in the Arab world, and and it is fully owned by Arab Mining Company.

Follow us on social media

ARMICO FUJAIRAH © All rights reserved 2022

Terms | Privacy policy Arab Mining Company – Fujairah