Blog / Arab Mining Company – Fujairah

About Basalt fiber

Basalt fiber is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase, pyroxene, and olivine. It is similar to fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber. It is used as a fireproof textile in the aerospace and automotive industries and can also be used as a composite to produce products such as camera tripods.

Manufacture

The technology of production of basalt continuous fiber (BCF) is a one-stage process: melting, homogenization of basalt and extraction of fibers. Basalt is heated only once. Further processing of BCF into materials is carried out using “cold technologies” with low energy costs.

Basalt fiber is made from a single material, crushed basalt, from a carefully chosen quarry source.[1] Basalt of high acidity (over 46% silica content[2]) and low iron content is considered desirable for fiber production.[3] Unlike with other composites, such as glass fiber, essentially no materials are added during its production. The basalt is simply washed and then melted.[4]

The manufacture of basalt fiber requires the melting of the crushed and washed basalt rock at about 1,500 °C (2,730 °F). The molten rock is then extruded through small nozzles to produce continuous filaments of basalt fiber.

The basalt fibers typically have a filament diameter of between 10 and 20 μm which is far enough above the respiratory limit of 5 μm to make basalt fiber a suitable replacement for asbestos.[5] They also have a high elastic modulus, resulting in high specific strength—three times that of steel.[6][7] Thin fiber is usually used for textile applications mainly for production of woven fabric. Thicker fiber is used in filament winding, for example, for production of compressed natural gas (CNG) cylinders or pipes. The thickest fiber is used for pultrusion, geogrid, unidirectional fabric, multiaxial fabric production and in form of chopped strand for concrete reinforcement. One of the most prospective applications for continuous basalt fiber and the most modern trend at the moment is production of basalt rebar that more and more substitutes traditional steel rebar on construction market.[8]

increasingly important

The study of natural fiber has become increasingly important in recent years due to the growing awareness of the need to protect ecological and environmental resources, including shrinking forest resources [3-4]. Despite the advantages of natural fibers over traditional ones (low cost, low density, acceptable specific strength properties, reduced tool wear and biodegradability), they suffer from several drawbacks, such as their hydrophilic nature (which affects the compatibility with hydrophobic polymeric matrix), the scattering in mechanical properties and the low processing temperature required. As a consequence, new reinforcement materials are currently studied. Such a new reinforcement could represent by basalt fiber [5-6]. Mineral fibers from basalt are not new, but their suitability as reinforcement in polymer composites is a relatively new issue. This emerging mineral fiber is natural, safe and easy to recycle. Basalt fibers have good physical and chemical properties, as well as good adhesion to metals, epoxies and glues. Not only do they boast good mechanical and chemical resistance, but also exhibit excellent thermal, electric and acoustic insulation properties. Due to all these favorable properties, Basalt fiber can be used in several applications in technical textile. In this paper brief introduction of its properties and applications of basalt fiber have been discussed.

green industrial material

Basalt fiber is known as green industrial material. Basalt fiber is colloquially known as the “21st-century nonpolluting green material”. Basalt is a natural material that is found in volcanic rocks originated from frozen lava, with a melting temperature comprised between 1500 ̊C and 1700 ̊C [7-8].

Basalt fibers are 100% natural and inert. Basalt products have no toxic reaction with air or water, are non-combustible and explosion proof. When in contact with other chemicals they produce no chemical reactions that may damage health or the environment. They have been tested and proven to be non-carcinogenic and non-toxic.

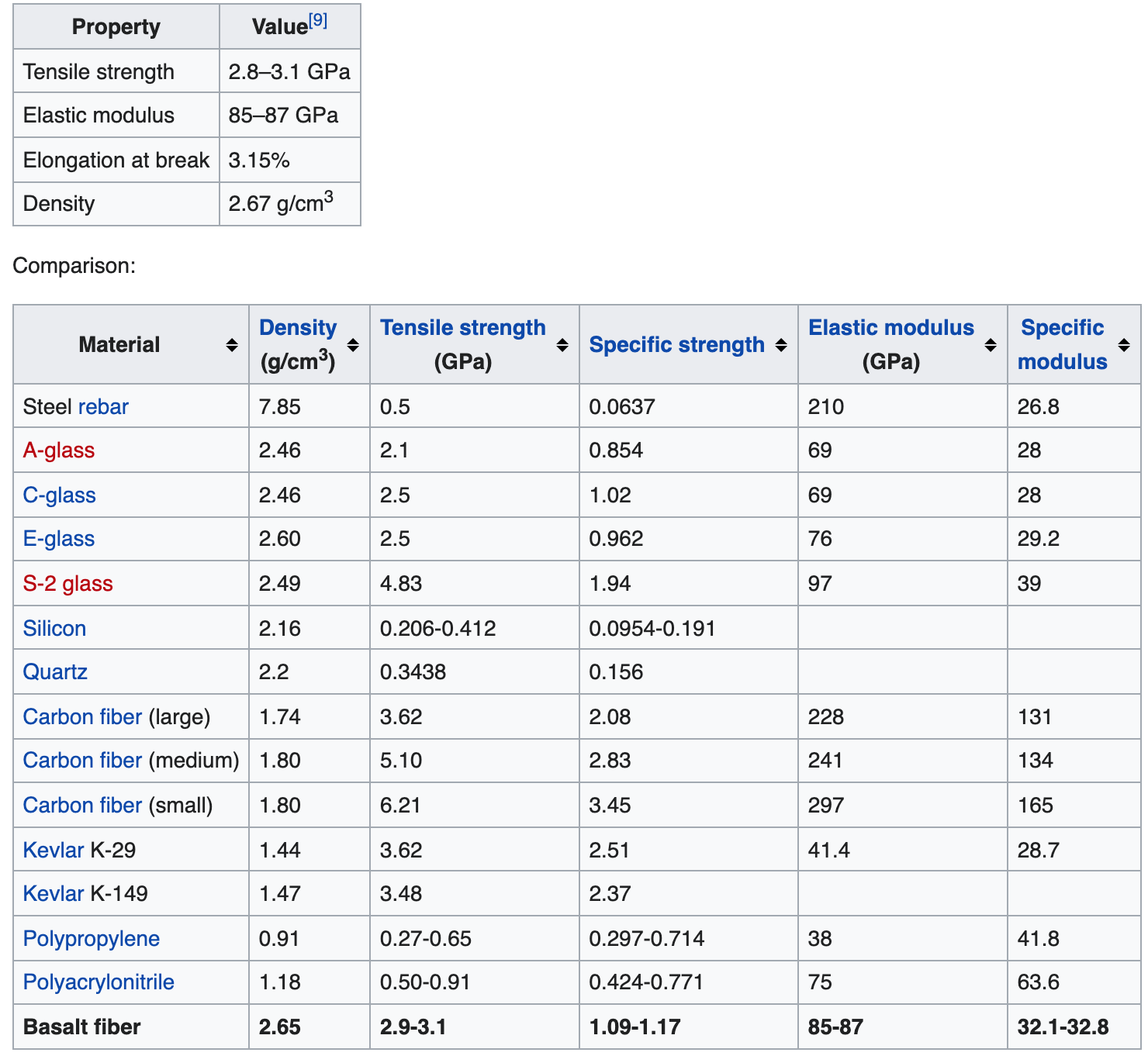

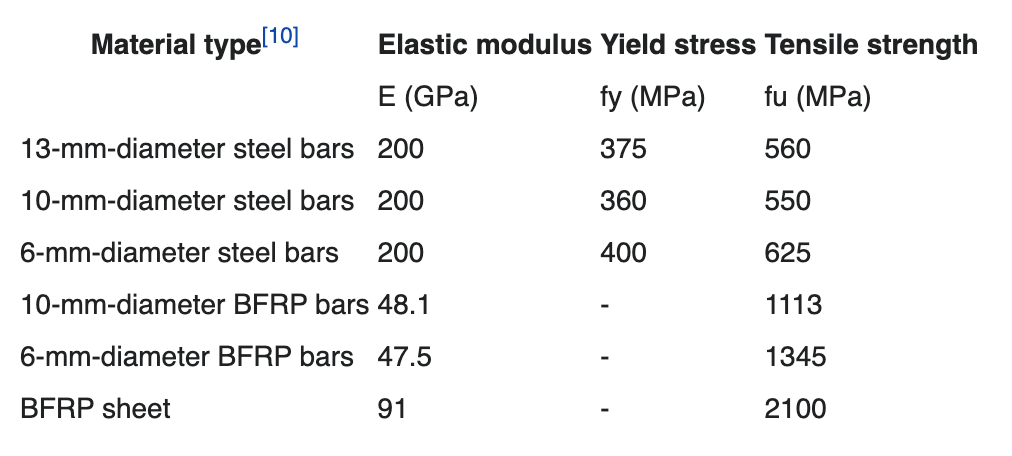

Properties

The table refers to the continuous basalt fiber specific producer. Data from all the manufacturers are different, the difference is sometimes very large values.

History

The first attempts to produce basalt fiber were made in the United States in 1923 by Paul Dhe who was granted U.S. Patent 1,462,446. These were further developed after World War II by researchers in the US, Europe and the Soviet Union especially for military and aerospace applications. Since declassification in 1995 basalt fibers have been used in a wider range of civilian applications.[11]

Schools

RWTH Aachen University. Every two year RWTH Aachen University’s Institut für Textiltechnik hosts the International Glass Fibers Symposium where basalt fiber is devoted a separate section. The university conducts regular research to study and improve basalt fiber properties. Textile concrete is also more corrosion-resistant and more malleable than conventional concrete. Replacement of carbon fibers with basalt fibers can significantly enhance the application fields of the innovative composite material that is textile concrete, says Andreas Koch.

The Institute for Lightweight Design at the TU Berlin[12]

The Institute for Lightweight Design Materials Science at the University of Hannover

The German Plastics Institute (DKI) in Darmstadt[13]

The Technical University of Dresden had contributed in the studying of basalt fibers. Textile reinforcements in concrete construction – basic research and applications. The Peter Offermann covers the range from the beginning of fundamental research work at the TU Dresden in the early 90s to the present. The idea that textile lattice structures made of high-performance threads for constructional reinforcement could open up completely new possibilities in construction was the starting point for today’s large research network. Textile reinforcements in concrete construction – basic research and applications. As a novelty, parallel applications to the research with the required approvals in individual cases, such as the world’s first textile reinforced concrete bridges and the upgrading of shell structures with the thinnest layers of textile concrete, are reported.

University of Applied Sciences Regensburg, Department of Mechanical Engineering. Mechanical characterization of basalt fibre reinforced plastic with different fabric reinforcements – Tensile tests and FE-calculations with representative volume elements (RVEs). Marco Romano, Ingo Ehrlich.[14]

Arab Mining company – Fujairah

Arab Mining Company – Fujairah was established in 2018 as a limited liability company with main focus toward the mining activities in the Arab world, and and it is fully owned by Arab Mining Company.

Follow us on social media

ARMICO FUJAIRAH © All rights reserved 2022

Terms | Privacy policy Arab Mining Company – Fujairah